Automated Conveyor Systems And Packaging Lines: Their Utmost Advantages And Importance

- mitsubishielectric1

- May 10, 2024

- 2 min read

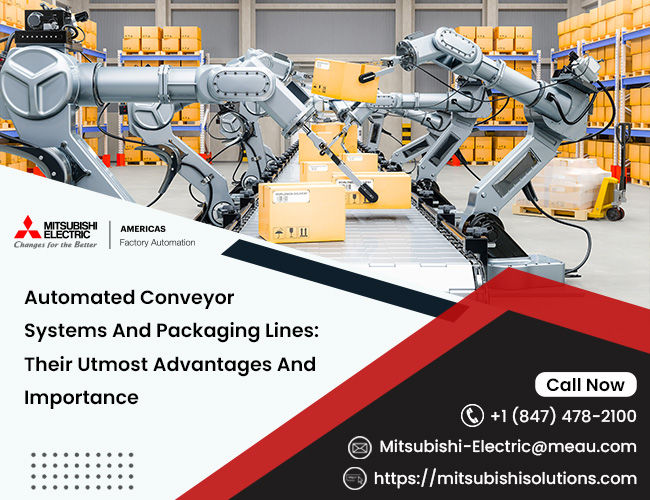

In today's competitive manufacturing landscape, efficiency is king. Every second counts, and any slowdown in production can impact your bottom line. This is where factory automation comes in, transforming the way products are made and moved. Among the key players in this revolution are automated conveyor systems, packaging lines, and pallet stackers. Delve into the importance of these automated solutions and explore how they contribute to a more streamlined and successful factory operation.

Automated conveyors move products continuously, eliminating delays and bottlenecks associated with manual handling. This translates to faster production cycles and increased output. By automating material movement, factories can significantly reduce their reliance on manual labor, freeing up human resources for more complex tasks. Manual material handling can lead to injuries. Automated conveyor systems eliminate this risk by removing the need for workers to lift or carry heavy items. Conveyor systems can be easily expanded or modified to accommodate changes in production volume or product type. This flexibility ensures your factory can adapt to future demands. Conveyor systems ensure consistent and gentle product handling, which minimizes the risk of damage during transportation.

Once your product is complete, it needs a secure and efficient packaging process. Enter automated packaging lines, a series of interconnected machines that handle various tasks like filling, sealing, labeling, and palletizing. Automated packaging lines operate at much faster speeds than manual processes, significantly boosting production output. Automated systems ensure consistent package quality, size, and weight, reducing the risk of errors and improving product presentation. Similar to conveyor systems, automated packaging lines free up human resources, allowing them to focus on other critical areas. Automated packaging eliminates repetitive and potentially dangerous tasks associated with manual packaging, promoting a safer work environment.

Pallets are the workhorses of warehouses and factories. But manually stacking them can be a time-consuming and physically demanding task. This is where automated pallet stackers come to the rescue. Automated stackers can load and unload pallets at significantly faster speeds than manual labor, boosting overall productivity. Stacking heavy pallets manually poses a serious injury risk. Automated stackers eliminate this risk, promoting a safer work environment. Automated stackers can optimize warehouse space by precisely stacking pallets to maximize storage capacity.

Automated stackers handle pallets with precision, minimizing the risk of product damage during the stacking process. These machines can be programmed to follow specific stacking patterns, ensuring accuracy and consistency in pallet storage. The true power of these automated solutions lies in their synergy. When conveyor systems seamlessly feed production lines, and automated stackers efficiently manage palletized products, the entire factory operation becomes a well-oiled machine.

Factory automation is not just a trend; it's the future of manufacturing. By implementing automated conveyor systems, packaging lines, and pallet stackers, factories can gain a significant competitive edge. These solutions offer numerous benefits, from increased efficiency and reduced costs to improved product quality and worker safety. As the technology continues to evolve, we can expect even more sophisticated automation solutions to emerge.

.png)

Comments